FOSB / FOUP Cleaning System

FOC300 series

FOSB / FOUP Cleaning System that Contributes to Quality Control, with Vacuum, Cleaning, and Inspection Technologies that has been Developed and Honed Over the Years Packed Into a Single Unit

In addition to improving the quality of wafers, advances in the miniaturization of semiconductor manufacturing processes have led to a need to remove residues such as particles, adsorbed gases, and moisture on the container side to prevent particles from adhering to wafers during shipping and inter-process transportation.

The FOC300 offers excellent cleaning and drying performance from load to unload (to pod and door dismantling, cleaning, drying, and assembly) with a fully automated system supporting 300mm wafer FOSB or FOUP. Various inspection functions are also available as options to aid in quality control.

We introduce products according to your specific needs!

Features

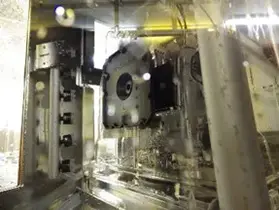

Excellent Cleaning and Drying Performance

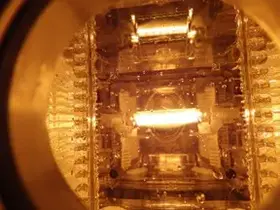

The FOC300 adopts our original two-fluid nozzle, and achieves a particle removal rate of 95% or higher and an (ammonia, etc.) absorbed gas (AMC) removal rate of 80% or higher—more than five times that of other existing products (*1). In the drying vacuum chamber, decompression treatment of 10Pa or less is applied in combination with a lamp heater, enabling effective moisture removal and preventing the adverse effects of humidity.

- *1Performance comparison on actual units of Shibaura Mechatronics system and systems offered by other companies.

[Options]

Door interior cleaning, coarse cleaning chamber, various inspection functions, etc.

We provide various functions to meet the needs of our customers. Please feel free to consult us.

Full Range of Optional Inspection Functions for Quality Control

Functions such as wastewater in-liquid particle measurement, gas analysis, humidity inspection, and visual inspection functions can be added to meet various needs.

In addition to quantifying cleaning effectiveness and drying results, it is also possible to formulate various control standards for FOSB and FOUP operation. Since it is possible to check particles not through the wafer but only with FOSB / FOUP, it is easy to isolate the impact on product performance, contributing to improvements in yield.

System Specifications

Throughput 30pcs / hr (*depending on recipe)

GEM300 standard support, online communication and various automated transport

SEMI, CE, etc., standard complaint

Related Information

Contact Us

- Fine Mechatronics Division