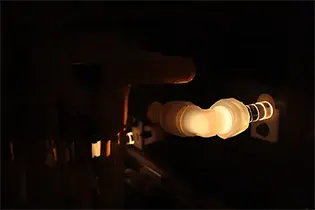

Hot- H3PO4 Wet Etching System

SC300-HT series

Largest Share (Based on the Survey Conducted by Shibaura Mechatronics) among the Single-Wafer Nitride Film Etching Processes

This Hot- H3PO4 Wet Etching System Supports 300mm Wafers

This Hot- H3PO4 wet etching system is continuously evolving as a nitride film etching system for cutting-edge logic devices.

Its features include etching profile control by the wafer proximity heater, high selectivity by silicon concentration control, and 2-in-1 configuration by the integration with a post-cleaning process. This contributes to the improvement of device reliability and yield.

We introduce products according to your specific needs!

Features

Control of Etching Profile

Capable of control of the amount of etching from the center to the end of a wafer with the zone-controlled wafer proximity heater, thereby minimizing the groundwork loss.

Achieved Both a High Etching Rate and a High Selection Ratio

Achieved a high selection ratio by controlling the silicon concentration in the phosphoric acid while maintaining the temperature of phosphoric acid at 160℃ or higher.

2-in-1 Concept

The phosphoric acid process and post-cleaning process are integrated into one system. A drying technology to counter pattern collapse can also be installed.

Related Information

Contact Us

- Fine Mechatronics Division